Optimization of melting behavior, durability and cost efficiency in glass and ceramics production

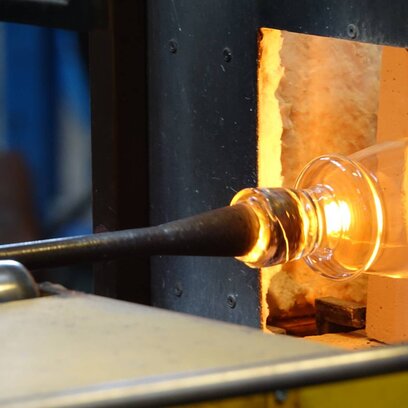

Fine Ground Calcium Carbonate (FGCC) in glass and ceramics production: flux, structural enhancer and process optimizer

Fine Ground Calcium Carbonate (FGCC) is an important functional mineral in glass and ceramics production, used as a fluxing agent, structural modifier and processing aid. Its role in controlling viscosity, optimizing thermal expansion and improving mechanical properties makes it indispensable in the production of flat glass, glass containers, specialty ceramics, tiles and sanitaryware.

Key Benefits of GCC in Glass & Ceramics

1. Fluxing agent in glass melting

- Reduction of melting temperature. CaCO₃ decomposes at a temperature of ~825 °C to form CaO, which acts as a flux, lowering the batch melting temperature and thereby reducing energy consumption.

- Improves homogeneity: enhances the interaction of silica and other oxides during glass formation.

- Participation in glass–silicate network formation. The CaO formed from calcium carbonate takes part in creating a stable Si–O–Ca–O network, improving thermal and chemical resistance.

See products

2. Structural Enhancement & Mechanical Strength

- Strength enhancement. CaO introduced via FGCC reinforces the ceramic matrix, improving impact resistance, fracture resistance and product durability.

- Control of thermal expansion. The addition of FGCC reduces the likelihood of cracking under sharp temperature gradients. FGCC granules with particle sizes of 3 µm and 5 µm have proven effective as optimal reinforcing fractions in ceramic products and glass composites.

See products

3. Viscosity control and processing efficiency

- Influence on rheology. In the glass industry, CaO controls melt viscosity, ensuring uniform flow of the material during flat glass drawing or bottle forming.

- Ceramic processing. FGCC improves the extrusion and pressing properties of powder bodies, facilitating the forming of tiles and sanitaryware while maintaining shape.

- Typical particle sizes: 2–5 µm are optimal for stable extrusion and defect reduction.

4. Surface quality & transparency in glass

- Transparency and bubble reduction. CaCO₃ contributes to glass melt homogenization, reducing the number of bubbles and micro-inclusions during melting, especially in combination with other refining agents.

- Smoothness and gloss in glazes. In glazes and coatings, FGCC increases hiding power, whiteness and surface smoothness.

- Recommended fractions: 1–2 µm for glazes and glass–ceramic coatings.

See products

5. Cost efficiency & sustainability

- Energy savings. By lowering the melting temperature when used in glass batches, calcium carbonate helps reduce fuel consumption and CO₂ emissions.

- Glass recycling. In combination with cullet (glass cullet), FGCC improves remelting by stabilizing the chemical composition.

- Sustainable formulations. Used in the development of glass with reduced borosilicate and alkali content while maintaining the physico-chemical balance.

Applications of FGCC in glass and ceramics

Flat glass & architectural glass

- Ensures stable melting and reduces the number of defects (inclusions, bubbles).

- Improves melt flow in float glass production.

- Recommended fractions: 3–5 µm for batch formulations.

Container and technical glass

- Increases impact resistance of bottles and jars by forming a uniform glass–silicate network.

- Reduces leaching from container walls in contact with food and beverages.

Ceramic tiles & sanitaryware

- Reduces shrinkage during drying and firing, minimizing deformation.

- Improves extrusion and pressing of ceramic bodies.

- Fractions of 2–5 µm provide an optimal balance between plasticity and shape stability.

Tableware & high-performance ceramics

- Improves glaze adhesion, whiteness and gloss.

- Controls thermal behavior, preventing microcracks during cooling.

Secondary glass recycling

- Provides chemical balancing during cullet processing.

- Improves energy balance and melting efficiency when reusing waste-containing batch.

High-quality Cemix FGCC for glass and ceramics

Cemix supplies high-purity FGCC grades specifically developed for glass, ceramics and special applications, providing process efficiency, structural strengthening and energy savings.

Contact us today for expert consultation and tailored FGCC solutions for your applications in the glass and ceramics industry.