Under-Tile Waterproofing

Waterproofing plays a particularly important role in wet areas such as bathrooms, kitchens, and laundry rooms. In these spaces, floors and walls are continuously exposed to the effects of water and vapor. Without adequate waterproofing, water can infiltrate the substrate and the walls, eventually causing serious damage. Moreover, leaking water can lead to the appearance of mold and fungi, which may also result in health problems.

The role of waterproofing in tiling

Tiling work can essentially be divided into four phases, each with its own role and significance. After preparation, the second phase is waterproofing.

It is important to keep in mind that this is what truly ensures the durability of the coverings. Indoors, it prevents the underlying layers from being damaged (for example, water seeping behind the tiles in a shower can damage the structure, larger amounts of water can cause leaks, and even a faulty washing machine can seriously damage the layers underneath). Outdoors, it prevents water from penetrating the structure, since in winter, frozen water expands and cracks everything apart.

Brushable/coatable waterproofing

Even in this stage, several options and materials are available, and the choice is primarily influenced by the expected load and cost-effectiveness factors. Some waterproofing materials can be applied safely under practically any circumstances, but in a generally low-load area (e.g. a bathroom), such a choice would be unnecessary and costly. The regulations concerning brushable waterproofing distinguish between indoor and outdoor applications, as well as materials resistant to chlorinated water and those suitable for drinking-water environments. The relevant standard markings are detailed below. Always check the product packaging or technical datasheet to make sure you select the product that meets your requirements!

Waterproofing product selector

Cemix waterproofing solutions and materials are available at this link. To help you choose the most optimal waterproofing material for your task, use the tiling–waterproofing product selector (see the figure below).

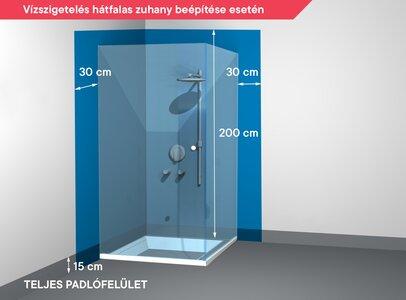

When it comes to waterproofing work, the devil is always in the details. Therefore, do not forget about positive and negative corner joints, pipe penetrations, or even door and window structures, for which special connection elements — compatible with the waterproofing material — are available individually.

Standard

The European Union standard (MSZ EN 14891) for brushable waterproofing under tiling defines three key basic criteria:

-

Adhesion strength

-

Water absorption

-

Crack-bridging ability

In addition, the standard also highlights higher quality requirements for certain properties, though meeting these is not mandatory.

Classification and Marking

The following symbols provide information about the properties defined in the standard:

-

CM – Cement-based, liquid-applied waterproofing product

-

DM – Dispersion resin-based, liquid-applied waterproofing product

-

RM – Reactive resin-based, liquid-applied waterproofing product

Optional characteristics:

-

O1 – Enhanced crack-bridging ability at low temperature (-5 °C)

-

O2 – Enhanced crack-bridging ability at very low temperature (-20 °C)

-

P – Resistance to chlorinated water (e.g. swimming pools)

Additional Notes

Based on the above, for example, Aquastop Flex is a flexible brushable waterproofing product with the rating “CM O2 P”, meaning it is cement-based, flexible down to -20 °C, and resistant to chlorinated water.

If a brushable waterproofing product only meets the basic requirements, it must not be used outdoors or in areas exposed to high water loads!

The standard does not cover the sulfate resistance of materials. This property becomes relevant when the surface comes into contact with contaminated (salt-laden) moisture or groundwater, which is particularly important for building sections below ground level, such as basements and plinth zones.

RELATED ARTICLES