What kind of return can we expect from thermal insulation?

The money spent on thermal insulation can gradually pay off through much lower utility bills (heating and cooling costs). Determining the exact amount of savings is not a simple task, as it depends on multiple factors. Calculations must take into account the size, layout, and orientation of the property, the condition of doors and windows, existing insulation, the parameters of the planned insulation system (insulation thickness, selected materials, installation method, etc.), and not least, current energy prices. Simply from lower heating bills, retrofitting an average family house with insulation can pay off within 3–5 years.

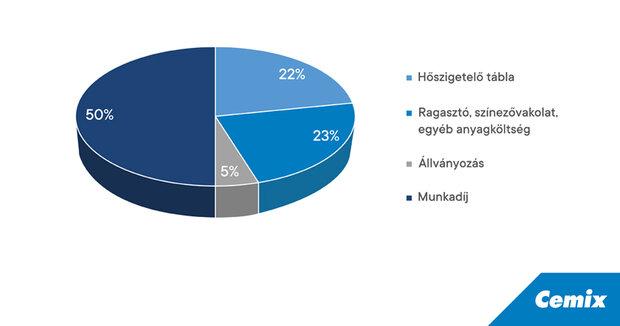

A significant portion of the investment cost comes from the contractor’s labor. This is not an area to cut corners, as a poorly or improperly installed insulation system can cause damages and repair costs that may far exceed the labor savings originally intended.

Another significant portion of the costs comes from the insulation boards themselves. The quality of the insulation boards determines the building’s energy performance, its future value, and the savings in operational costs. Therefore, when planning insulation work, it is important to carefully select the type and thickness of the insulation board.

When choosing the right material, one must consider the type of wall structure and the environment in which the board will be installed. When determining thickness, the desired level of energy efficiency must be taken into account. Using normal EPS boards with double the thickness increases investment costs by about 15%, but energy savings reach approximately 40%. When using graphite EPS boards instead of normal EPS boards of the same thickness, costs increase by around 10%, while energy savings amount to roughly 15%.

The remaining portion of the investment cost, about 23%, comes from the materials for system adhesive, colored plaster, and supplementary products. This includes the cost of the system adhesive used to fix and protect the insulation boards, which accounts for roughly 3% of the total cost. Choosing a cheaper but low-quality adhesive does not significantly reduce expenses and may increase the risk of damage to the entire insulation system, and consequently, the facade.

By using dowels, which are part of the supplementary products, a properly stable and therefore more durable insulation system can be installed. Various profiles, also in this category, ensure clean, aesthetically pleasing edges and, in some cases, provide a watertight connection between structural elements. While their cost is only a fraction of the total investment, their use results in a more durable and visually appealing thermal insulation system.