Selection of Masonry Mortar

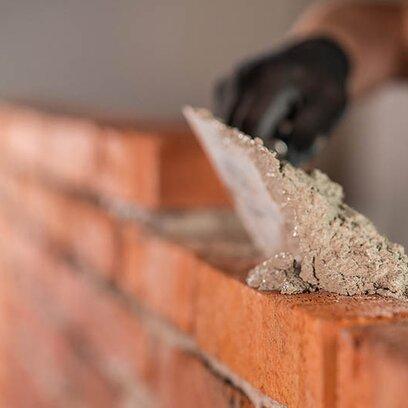

When constructing new buildings, the mortar is chosen based on the wall material and the expected load. For clinker bricks, ceramic blocks, and Ytong blocks, mortars with technical properties suitable for the specific material are used.

For certain structures, such as glass block walls, special masonry mortars are required to ensure the strength and stability of the construction.

Main Types of Masonry Mortars

Masonry mortars can be classified according to different criteria, but the most common division is based on their purpose and composition.

In the past, clay, lime, gypsum, trass, and in some regions, cement—or mixtures of these—were most often used as binders to join and secure masonry elements.

Today, the most widely used binders are lime (slaked lime or hydrated lime) and cement.

Interestingly, for the restoration of architectural monuments or ruins, mortars with hydraulic binders containing hydrated lime and trass are used, ensuring durability and strength for restoration work.

Properties of Masonry Mortars

One of the most important properties of masonry mortars is compressive strength, which determines whether the material can withstand the loads imposed by the wall structure itself.

The properties of masonry mortars are regulated by the European standard EN 998-2, which sets requirements for factory-prepared mortars used in the construction of walls, columns, and partitions (laying, precise alignment, joint finishing). According to this standard, the manufacturer must conduct initial type tests after developing a product to confirm its compliance with European requirements.

For fresh mortars, the following parameters are specified:

-

Working time (time suitable for handling)

-

Chloride content

-

Air content

-

Density

-

(For thin-layer mortars) the period during which adjustments can be made

For hardened mortars, the following are determined:

-

Compressive strength

-

Adhesion strength (bond with the surface)

-

Density

The numbers in the names of Cemix masonry mortars indicate the compressive strength class after hardening. For example: MM1, MM3, MM5, and MM10 correspond to classes M1, M2.5, M5, and M10 according to the harmonized European standard. The mortars must meet the declared compressive strength values:

-

MM1 > 1 N/mm²

-

MM3 > 2.5 N/mm²

-

MM5 > 5 N/mm²

-

MM10 > 10 N/mm², and so on.

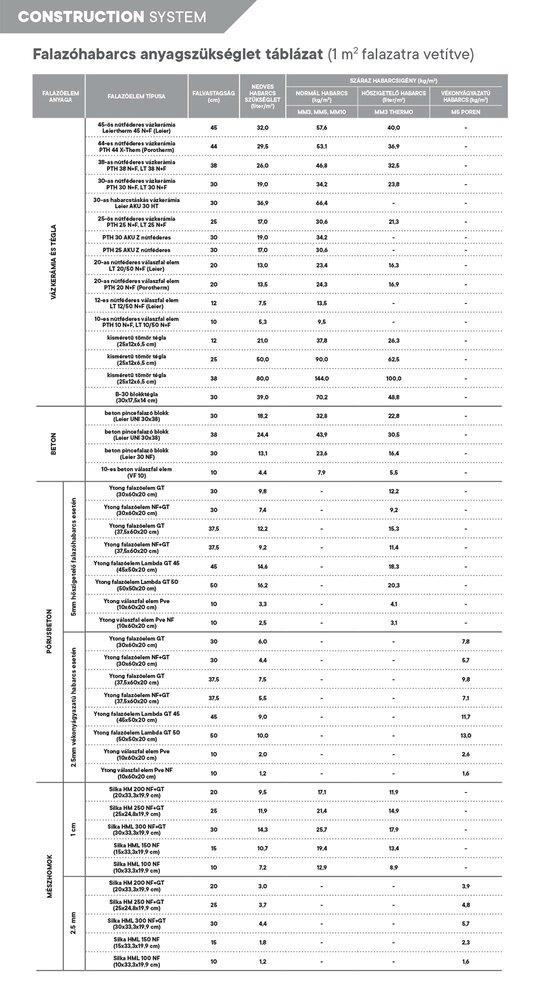

Material Consumption

The exact requirement for masonry mortar is determined by the manufacturer of the masonry units. The table below provides approximate consumption values for wet and dry mortar for various types of masonry elements.

Technical documentation for masonry mortars always recommends strictly following the specified amount of mixing water. This ensures the correct consistency of the mortar, making it easier to apply while guaranteeing the necessary bond strength between masonry units.

If too little water is used, the mortar becomes thick, making it difficult to apply, impossible to level surface irregularities, and it will adhere poorly to the masonry units, failing to create a reliable connection.

If too much water is added, the mortar becomes too fluid, making it unable to stay on the surface of the units, reducing adhesion and preventing even load distribution. In addition, excess water negatively affects the strength of the hardened mortar.

Accounting for Temperature and Moisture Effects When Selecting Mortar

Masonry mortar not only serves to connect masonry units but also plays an important role in the thermal and vapor-permeable properties of a building.

This is especially important for low-energy or passive houses, where optimizing thermal insulation is a priority. Thermal-insulating mortars help reduce the formation of thermal bridges, contributing to energy efficiency.

Additionally, the vapor permeability of the mortar is crucial, particularly for masonry made of natural materials or in the restoration of old buildings, where it is necessary to maintain the walls’ ability to “breathe.”

Durability and Environmentally Friendly Solutions

In modern construction, increasing attention is being paid to environmental responsibility, so it is important to consider the ecological impact of masonry mortar when making a choice.

Mortars based on lime or trass have a lower carbon footprint (CO₂) compared to high-cement options. In addition, more and more manufacturers offer mortars made with recycled materials or produced using energy-efficient technologies.

For contractors and investors focused on sustainable architecture, such solutions are important not only for environmental protection but also as a marketing advantage.