To determine the substrate requirements, it is necessary to define the purpose of the surfaced area. Consider how this surface will be used. Keep in mind that extreme operating conditions may vary depending on the room.

Note: When designing, the amount and type of load that will occur during the use of this space should be taken into account.

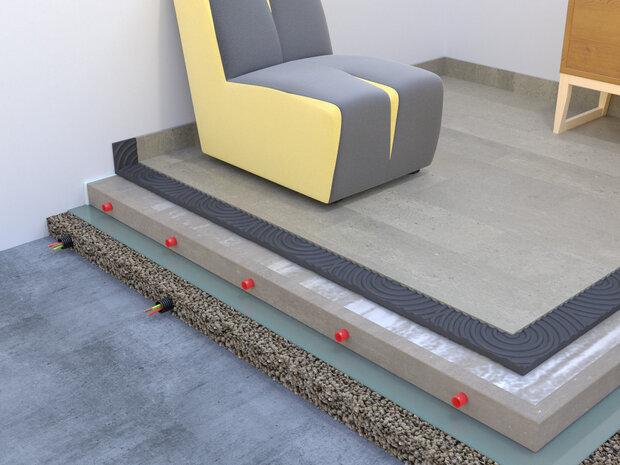

Most floor structures consist of four main components. Based on the requirements, it is determined which layers are necessary.

The load-bearing structure is a structural element of the building, designed by an architect or structural engineer.

This layer must perform several functions at the same time:

Thermal and sound insulation

Mechanical and electrical installations

Waterproofing

The load distribution layer serves two main functions: it supports the floor covering and distributes the load onto the floor structure. Additionally, underfloor heating pipes can be installed within this layer.

In utility areas, it can be installed without a floor covering.

Role of the layers:

Load distribution function: In daily use, floors are subjected to point loads, such as high heels, furniture, chairs, and similar. Load distribution means transferring these point loads over a larger area. Depending on the operating conditions, the appropriate type of screed should be used (for example, gypsum-based screeds should not be used outdoors or in wet areas; for higher loads, materials with a compressive strength of at least 30 N/mm² are required).

The load distribution function helps to evenly spread mechanical stresses on the floor, which are often concentrated as point loads in everyday life. The highest point load is created by a high heel. To evenly distribute this load, it must be transferred over a larger area. Different types of screed are used depending on the conditions. For example, gypsum-based screeds are not suitable for outdoor or wet areas. For higher loads, screeds with minimal gypsum content and a compressive strength of at least 30 N/mm² should be used.

The most important properties of a screed are indicated in its marking according to the standard (EN 13813):

-

(CT) — cement screed

-

(CA) — calcium sulfate (gypsum) screed

-

(MA) — magnesite screed

-

(SR) — synthetic resin screed

-

(AS) — asphalt screed

-

(C) — compressive strength (N/mm²)

-

(F) — flexural strength (N/mm²)

(Other properties, such as wear resistance, adhesion strength, and more, may also be included.)

For example, Estrich ZE 30 is a certified product marked CT C30 F5, meaning it is a factory-prepared dry mix with a cement binder, compressive strength of 30 N/mm², and flexural strength of 5 N/mm².

Underfloor heating pipe installation:

Underfloor heating is increasingly used alongside traditional heating systems such as radiators, fireplaces, and stoves. Both electric and water-based underfloor heating solutions are available.

Level surface and design:

By choosing the screed height, we determine the final level of the floor covering, while proper substrate preparation ensures a suitable surface for future finishes.

The tile size and type of covering affect the quality of the screed surface.

For installing large rigid coverings or bonding underfloor heating elements, a flat surface is required, which may necessitate self-leveling screeds or poured leveling compounds.

This layer is an important element in floor design.

The choice of material, its thickness, and installation method directly affect the preparation and construction of the base layer (screed), load distribution, and the durability of the structure. When designing, these parameters must be evaluated, the operating conditions of the room considered, and the layer’s characteristics adjusted to ensure the strength, stability, and longevity of the entire floor.

Cover thickness

The thickness of the covering material and the adhesive layers required for its installation determine the overall floor covering thickness.

The adhesive layer is 3–5 mm for small and medium-sized tiles and about 5 mm for large-format tiles. Natural stone is not glued but laid on a thick bedding mortar layer (20–30 mm).

A thin (around 1 mm) dispersion adhesive is used for fixing parquet, linoleum, and PVC.

Surfaces exposed to water are pre-treated with waterproofing, with a layer thickness of 1.5–4 mm.

If proper leveling of the screed surface cannot be achieved, the thickness of a leveling layer must also be taken into account when determining the layer structure.

Screed installation method:

Bonded or contact screed, where the base surface and the screed work together.

Sliding screed, where a thin separation layer (film or waterproofing) is placed between the substrate and the screed. The purpose is to allow the base surface and screed to move independently of each other.

Floating screed, where a layer of thermal or sound insulation is installed between the substrate and the screed. Proper load distribution must also be ensured in this case.

Minimum layer thickness:

-

2.5 cm for a bonded calcium sulfate screed

-

3 cm for a cement screed

-

3.5–4.5 cm for a floating screed

For a floating screed with underfloor heating, the minimum thickness is measured from the top level of the pipes embedded in the screed.

For higher loads, the layer thickness should be increased, or a stronger material should be used.

The minimum thickness of the thermal insulation layer is determined based on thermal protection requirements and the maximum pipe crossing or slope within the layer. The recommended thickness is 30–80 mm. A common mistake is trying to fit too many pipes in this layer without considering the total height of intersecting pipes and possible slopes.

The thickness and type of sound insulation are selected based on acoustic calculations. The typical sound insulation thickness is 20–50 mm.

Required slopes are created using the thermal insulation layer or a concrete layer laid directly on the load-bearing structure. A common mistake is failing to account for the slope direction (2%) and the waterproofing layer thickness when determining the terrace plane.