Substrate preparation

Recommendations for thorough substrate preparation

To ensure the strength, even curing, and durability of the screed, it is recommended to follow these requirements:

-

The substrate must be strong, dry, clean, and free of dust, oils, and other contaminants.

-

All weakly bonded or loose elements that could reduce screed adhesion must be removed from the surface.

-

Any cracks, potholes, or defects in the substrate should be repaired in advance, no later than a few days before screed installation.

-

Before applying primer 2613, ensure that the substrate absorbs moisture evenly, does not crumble, and has sufficient strength. This check should be performed at least one day prior to starting work.

-

The method of substrate preparation depends on its type (concrete, cement screed, monolith) and the chosen floor system.

What you need to know about primers and adhesion bridges?

Primers and adhesion bridges are liquid compounds applied in a thin layer to prepare the substrate for the screed and subsequent layers.

- A primer is used on absorbent substrates to reduce water absorption and ensure even screed curing.

- A deep-penetrating primer strengthens weak or chalky surfaces, as well as drywall, providing reliable adhesion with the screed.

- An adhesion bridge is used on smooth or non-absorbent substrates to connect materials with different adhesion properties and prevent screed delamination.

Why use a primer before installing the screed?

-

Using a primer before installing the screed ensures reliable adhesion to the substrate and stable curing of the floor. The primer performs several functions:

-

Reduces the substrate’s water absorption and prevents moisture from being drawn out of the screed, which is essential for strong bonding with the base.

-

Equalizes the surface’s absorbency and ensures even screed drying, especially when using poured or self-leveling floors.

-

Strengthens slightly porous substrates, increasing their durability.

-

Improves adhesion between material layers, preventing screed delamination and damage to the floor covering.

Substrate preparation for screeds over 100 mm thick

When it is necessary to raise the floor level by more than 100 mm, the screed is installed over a pre-prepared base layer. This approach reduces the load on the floor slab, ensures a stable substrate, and optimizes the use of screed materials. Expanded clay or crushed stone is typically used as the base layer, with the choice of material depending on the type of substrate and operating conditions.

Substrate preparation includes leveling the surface, filling the base layer in stages, and compacting it thoroughly to achieve a strong and stable surface. Insufficient compaction of the base layer can lead to settlement and damage to the screed during use.

After the base layer is formed, a separation layer is installed to prevent moisture loss from the screed into the substrate and to ensure proper curing. Polyethylene film or rolled waterproofing is used as the separation layer, laid across the entire surface with overlaps of 100–150 mm and extended up the walls above the future screed level. Any damage to the separation layer is not permitted.

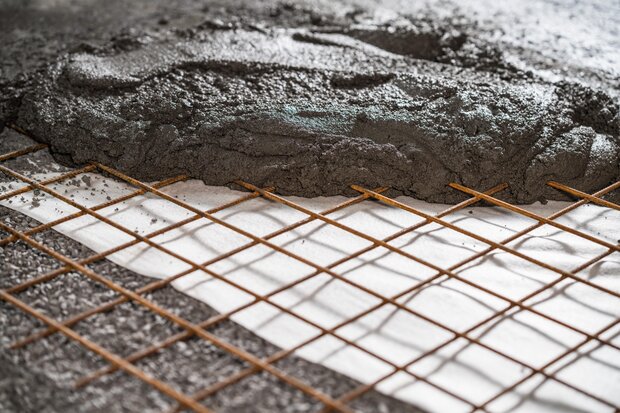

Screed reinforcement

Screed reinforcement is applied when the layer thickness is increased (usually over 60–70 mm), when installing a screed over a base layer, and in areas with high loads. Properly installed reinforcement improves crack resistance and floor durability.

Key rules for reinforcement:

-

Material: Metal mesh with 50×50 mm or 100×100 mm openings, wire diameter 4–6 mm depending on screed thickness and load.

-

Overlap: Adjacent sheets or pieces of mesh should overlap by 100–150 mm on all sides.

-

Position in the screed: The mesh is placed on special supports (plastic “crocodile” clips or stands) so that it sits within the screed, approximately 1/3–1/2 of the thickness from the top surface.

-

Installation: The mesh is laid after the separation layer (film or waterproofing) and must not touch the substrate or walls to prevent corrosion and maintain screed integrity.

-

Additional reinforcement: In areas with high loads or long spans, double reinforcement (two layers of mesh with supports) can be used.

Proper reinforcement ensures even load distribution, prevents cracking, and increases the durability of the screed.

Transition to screed installation

After thorough substrate preparation including surface leveling, installation of a base layer if necessary, placement of the separation layer, reinforcement, and application of primer or an adhesion bridge the screed can be installed. Following all these steps ensures floor strength, even curing, and durability, as well as reliable adhesion between all layers of the floor system.