Waterproofing beneath tiling

Waterproofing is especially essential in wet areas such as bathrooms, kitchens, and laundry rooms. In these spaces, floors and walls are constantly exposed to water and steam. If waterproofing is missing or incorrectly applied, moisture gradually penetrates the substrate and walls, leading to deterioration. In addition, accumulated moisture creates favorable conditions for mold and fungal growth, which can result not only in damage to finishes but also in health issues.

The role of waterproofing in tile installations

Tiling work is usually divided into four key stages, each playing an important role. The second step after substrate preparation is waterproofing.

This stage is critical for the durability of the covering. Indoors, waterproofing protects the underlying layers from damage: water that gets behind tiles in showers or bathrooms can compromise the structure, cause leaks, and damage the substrate. Similarly, a malfunctioning washing machine can damage the layers beneath the covering. Outdoors, waterproofing prevents moisture penetration, which can expand when frozen in winter and lead to cracks and structural damage.

Coating or paint-on waterproofing

At this stage, several options and materials are available, and the choice primarily depends on the expected load and cost-effectiveness. Some waterproofing materials can be used in almost any conditions; however, for low-load areas (such as a bathroom), this would be excessive and expensive.

Regulations for coating waterproofing distinguish materials for indoor and outdoor use, materials resistant to chlorinated water, and those suitable for potable water systems. Standard designations are provided below. Always check the product packaging or technical datasheet to ensure the selected material meets your requirements!

Waterproofing Products Selector

Cemix waterproofing solutions and materials are available at the link provided. To select the most suitable waterproofing material for your project, use the product selector for tiles and waterproofing (see the diagram below).

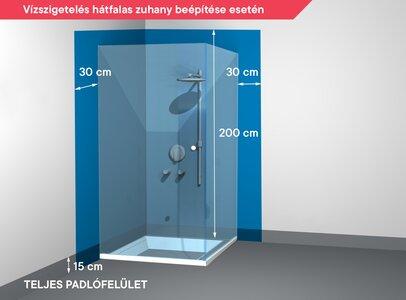

When it comes to waterproofing work, the devil is in the details. Therefore, don’t forget about positive and negative corners, pipe penetrations, as well as door and window structures, for which special connection elements are provided. These elements are selected individually and must be compatible with the waterproofing material.

Standard

The European standard (MSZ EN 14891) for coating waterproofing under tiles defines three key criteria:

-

Adhesion strength

-

Water absorption

-

Crack-bridging ability

In addition, the standard specifies enhanced requirements for certain properties, the fulfillment of which is not mandatory.

Classification and labeling

The following designations indicate properties defined by the standard:

-

CM – cement-based liquid-applied waterproofing

-

DM – dispersion resin liquid-applied waterproofing

-

RM – reactive resin liquid-applied waterproofing

Additional characteristics:

-

O1 – enhanced crack-bridging ability at low temperature (-5 °C)

-

O2 – enhanced crack-bridging ability at very low temperature (-20 °C)

-

P – resistance to chlorinated water (e.g., in swimming pools)

Additional notes

For example, Aquastop Flex is a flexible coating waterproofing with the rating CM O2 P, which means: cement-based, flexible down to -20 °C, and resistant to chlorinated water.

If a coating waterproofing only meets the basic requirements, it cannot be used outdoors or in areas with high moisture exposure.

The standard does not cover sulfate resistance. This property becomes important when the surface is in contact with contaminated (salt-containing) moisture or groundwater, which is especially relevant for underground parts of buildings, such as basements and plinth areas.

Related articles